Timberkits Clapping Pig

Note that this model is the "Clapping Pig" on the US Timberkits website, but is called "Perky Porky" on the UK Timberkits website.

Finished model.

Finished model.

The crankshaft has two opposing inner cams that operate on a horizontal disk. These components control the up and down and back and forth movement of the head. Note the stop-dowels associated with the horizontal disk, which limit the back and forth movement of the head. A pair of outer triangular cams operate levers, which control the arm linkage.

Crankshaft and cams.

Shown below are the linkages that operate the arms. I have the two triangular cams lined up with each other as instructed. This results in three claps per revolution of the crankshaft. However, I could have assembled the crankshaft to have the triangular cams oppose each other. Note that the Drummer employes a pair of opposing triangular cams to operate the left arm. So I think the result would have been twice as many claps with less arm movement. An interesting variation to consider.

Arm linkage.

Unlike most Timberkits models, the parts map included with this kit was unlabeled. It's up to the builder to identify which parts are which.

Box, parts and instructions (note the unlabeled parts map).

The instructions call for a spacer to be glued to the outside ends of the two frame shafts. But the spacers are not needed. So I cut the shafts flush with the frame. These extra spacers would prove useful as explained below.

Shafts cut flush with the outside of the frame.

I glued the upper arms too far back on the body. The forearms looked like they were going to get hung up on the chest. So instead of using the small spacers as instructed, I used the larger spacers left over from the frame shafts. The forearms clear the chest with the larger spacers. Note that the holes in the larger spacers are too big. But they need not be glued and work just fine as is.

Here are the forearms with the larger spacers. Also shown are the smaller spacers that went unused.

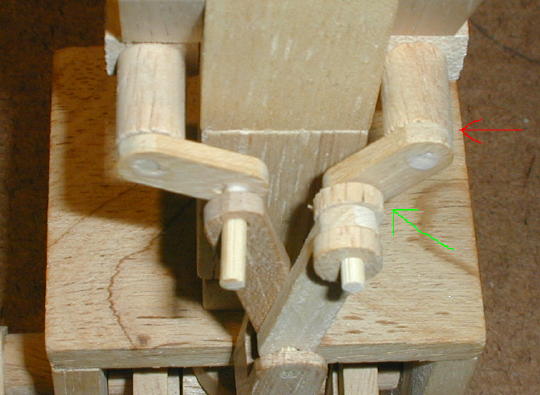

The dowel that operates the right arm ended up being too short to assemble the link spacers as instructed. As shown below, I moved one of the spacers from the arm dowel (red arrow) to the link dowel (green arrow). My spacer configuration does not seem to have impaired the model's operation.

Link and spacer arrangement.

Don't install the jaw into the head until the rest of the model is finished. The length of the jaw dowel may need to be adjusted depending on how the head moves relative to the collar.

Jaw dowel.

I had a few leftover parts that the instructions do not appear to identify.

Leftover parts.